Release Time: 2024-11-05Source:

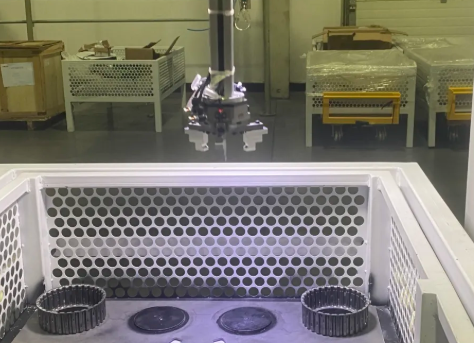

Intelligent truss type CNC lathe production line

This production line consists of an upper system, CNC lathe, truss robot, inverted 6-axis collaborative robot, vision system, loading and unloading system and silo, flipping mechanism, sampling slide table, safety protection, etc. The entire line has been delivered and is running well, solving the customer's production bottleneck problem. It has become the main production equipment on site and has received high praise from customers.

Unmanned, efficient and stable

The application of stable and efficient automated and intelligent machining production lines is an effective way for automobile manufacturers to achieve cost reduction and efficiency improvement. At the same time, it also represents the strong manufacturing capabilities of automobile manufacturers.

The integration of high-quality CNC lathes, truss manipulators, articulated robots, and vision systems, combined with Ultra Light's independently developed electrical control, enables the production line to have stable and efficient operation capabilities. Workers can complete the loading and unloading of blanks and finished products at the loading and unloading positions according to their own production needs. The production line also reserves software and hardware interfaces for future integration with AGV systems, providing unlimited possibilities for customers to achieve smart factories in the future.

Features: Free stacking and disorderly grasping of workpieces

Reviewing Budget Deviations and Planning for a New Journey—Ultra Light Holds the 2026 Annual Budget Preparation Meeting

Targeting Market Gaps and Strengthening Development Foundations | Establishment of Ultra Light Craft Technology Test Center

Ultra Light: The Pre-Acceptance of the Huade Cylinder Block Machining Project Concludes Successfully, Empowering Intelligent Manufacturing Upgrades in the Hydraulic Industry!

Ultra Light: Driving Traditional Manufacturing Towards a New Path of Digital and Intelligent Green Synergy Through Smart Manufacturing

Building a New Future for the Enterprise | The Official Establishment of Three Key Organizations: Ultra Light Party Branch, Trade Union, and Women's Group

Message

Message*Full Name

*Telephone

Message