Release Time: 2025-10-15Source:Ultra Light

Preface

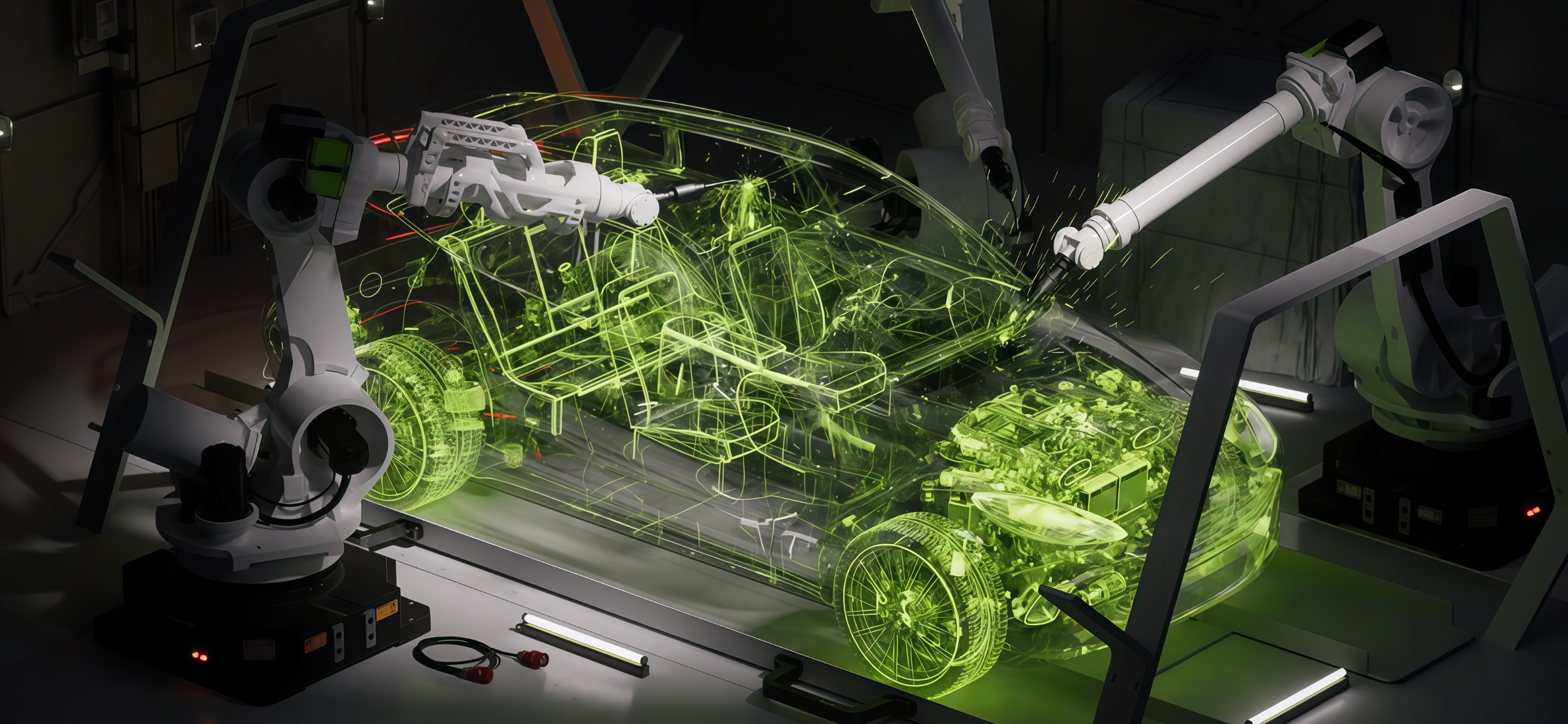

In the context of the increasingly widespread and profound application of intelligent manufacturing, "digitalization and intelligence" is no longer a slogan, but a necessary path for the survival and development of enterprises. Faced with increasingly fierce market competition, rising labor costs, and customers' strict requirements for quality and delivery time, traditional production management models have become inadequate.Ultra Light continues to deeply cultivate the field of intelligent manufacturing in mechanical processing, and has gained the trust and favor of many large leading enterprises with its mature Manufacturing Execution System (MES) solutions. It has provided overall solutions for factory upgrades to customers such as Tongjia Hongrui, Fuchuang Precision, and China Electronics, and is also becoming a strategic partner for many manufacturing enterprises to move towards digital factories, injecting strong impetus into the intelligent upgrading of enterprises.

Application scenarios and stages

Ultra Light's MES system is deeply compatible with the characteristics of mechanical processing and equipment manufacturing, providing customers with software products and solutions that better meet their practical needs. It can achieve rapid compatibility with customers' production systems, allowing grassroots users to quickly get started and play the role of the system in the shortest possible time.

PART1 Highly flexible and precise customization

The Ultra Light MES system has the characteristics of high flexibility and customizability, which can accurately adapt to the production characteristics and individual needs of different enterprises. It can achieve collaborative integration of basic data for complex process requirements of enterprises. For enterprises that have already deployed ERP systems, the system captures core information at regular intervals and synchronizes it through pre-set standardized interfaces. During the synchronization process, manual supplementation and correction are supported to ensure data integrity and consistency; For enterprises that have not yet built an upper level system, the system has an independent basic data maintenance module built-in, which supports the full lifecycle management of materials, processes, equipment and other data, avoiding information deviation and efficiency loss caused by manual duplicate input from the source.

In the process management stage, the system takes "process tasks" as the core carrier and constructs a full process digital control system. By associating production requirements with contract numbers, automatically screen the list of pending parts, generate process tasks based on preset process templates, and intelligently assign them to corresponding process engineers. At the same time, extract standardized process data packages to assist process engineers in quickly completing process design. On site workshop staff can directly call and print customized process documents containing QR codes through industrial all-in-one machines or mobile terminals. The documents are associated with production tasks in real time, avoiding version confusion and significantly shortening the process preparation cycle.

PART2 Intelligent scheduling and efficient production

In response to the common pain points faced by manufacturing enterprises, such as "disorderly insertion of orders and difficult scheduling", the Ultra Light MES system is equipped with an independently developed advanced planning and scheduling (APS) module. This module is based on an improved genetic algorithm and integrates constraint theory (TOC), with dynamic scheduling capabilities under multi-dimensional constraints, completely replacing the experience dependent mode of traditional manual scheduling.

The system supports three strategies: reverse scheduling (pushing production nodes back from delivery date), forward scheduling (pushing production nodes forward from start date), and mixed scheduling, which can be flexibly selected according to the production type of the enterprise.

In the face of emergency order insertion or rejection scenarios, the system has the ability to "dynamically rearrange" - scheduling personnel only need to add or remove pending tasks in the system, and the system will update the scheduling plan in real time based on the current production status (such as the progress of work orders that have already started or the availability of equipment). Meanwhile, scheduling personnel can also manually adjust scheduling parameters through a visual scheduling interface.

In order to achieve transparent control of the production process, the system has opened the interface with the WeChat official account. Customers can log in through the official account authorization to view the production nodes of their orders in real time (such as blank warehousing, machining completion, final inspection qualification), key process progress and estimated delivery time, and improve customer satisfaction.

PART3 Real time data collection and precise decision-making

In the context of intelligent manufacturing, data has become the core asset of production management. The Ultra Light MES system has built a full chain data loop of "collection transmission analysis application", relying on industrial Internet of Things technology to achieve real-time and accurate collection and intelligent analysis of production data.

In the data collection process, the system adopts a "multimodal fusion" collection strategy to cover the data requirements of the entire workshop scene: for discrete processes, process flow data collection is achieved through scanning guns or PDA scanning codes; For device data, it is connected to the device PLC and DNC systems through OPC UA protocol to collect real-time device data; For quality inspection data, support quality inspectors to input measured values online through mobile terminals, automatically capture inspection results, and avoid manual input errors; For material consumption data, the unit product material consumption quota is automatically calculated by associating the material requisition form, return form, and production task.

After processing and analyzing the collected data, the results are presented in the form of visual reports, which support viewing on both PC (web interface) and mobile (app/mini program). The management does not need to rely on post production statistical reports, and can accurately grasp production dynamics through real-time data.

PART4 Material Management and Cost Control

In response to the pain points of inventory management in manufacturing enterprises, such as discrepancies between accounts and goods, material waste, and delayed delivery, the material management module of Ultra Light MES system, with "barcoding" as the core technology, has constructed a full process digital control system covering "raw material storage production material requisition work in progress product transportation finished product storage", achieving precise traceability of material flow and effective control of inventory costs.

When raw materials are put into storage, the system and ERP collaborate in real time: ERP generates a raw material transfer order and synchronizes it to MES. The warehouse keeper uses PDA to scan the raw material barcode (including drawing number, batch, quantity) for verification, and after confirmation, completes the storage and updates the ledger; The emergency material requisition scenario supports "pre storage". After the warehouse keeper verifies the physical object, temporary inventory is generated in MES, and the formal data is synchronized after ERP review to avoid discrepancies between accounts and goods.

In the production material requisition process, the system automatically generates a material requisition form with a unique barcode according to the task, and the warehouse labels the material according to the reminder; The operator scans the material requisition form and material barcode, and the system automatically verifies the information without the need for manual verification, preventing errors and omissions in receiving; The assembly order supports a dual mode of "total code+detailed barcode" for staggered material requisition, and also has a material requisition limit warning to prevent waste.

A scanning code transfer point is set up for product transfer. After the process is completed, the system pushes the task to the transfer worker's PDA, scans the code for shipment, delivery, and records the trajectory. The automated workshop can be connected to AGV for unmanned transfer, and the entire process can be traced.

Synchronize ERP/WMS inventory management, achieve first in, first out, set up safety stock warnings, calculate material turnover to identify obsolete materials, assist in optimizing procurement plans, and reduce inventory costs.

PART5 Quality traceability and quality assurance

Quality is the core competitiveness of manufacturing enterprises. The Ultra Light MES system has established a full process quality control system of "prevention in advance, control during the process, and traceability after the fact", which meets the requirements of quality management systems such as IATF16949 and achieves full lifecycle traceability of product quality.

In the pre prevention stage, the system supports the "Custom Inspection Procedure" function - quality management personnel can configure standard data for each process based on the part process route. When the production task reaches the inspection node, the system automatically generates the inspection task and pushes it to the mobile end of the quality inspector to ensure standardized execution of the inspection work.

In the process of management and control, the system has established a "real-time abnormal reporting rapid response" mechanism. Real time push of abnormal information to relevant responsible persons, supporting multi-channel reminders such as SMS and system messages. After receiving, responsible persons can assign processing personnel online, track processing progress, and shorten abnormal response time.

In the post traceability process, the system relies on "batch management+barcoding" technology to build a full process data traceability chain from "raw material warehousing - production processing - finished product outbound". Each material (raw material, semi-finished product, finished product) is assigned a unique barcode, which is associated with various data. When quality problems occur, quality management personnel scan the finished product barcode to quickly locate the source of the problem and improve product quality stability.

PART6 Comprehensive improvement and sustainable development

The Ultra Light MES system is not a single function management tool, but a collaborative management platform covering seven core links: process, order, scheduling, workshop, equipment, quality, and inventory. Through data exchange and business collaboration between modules, it provides full process support for enterprises to move towards intelligent manufacturing.

At the level of NC program management, the system implements standardized control: builds a central database for NC programs, supporting centralized storage of NC programs for various CNC systems; Support offline programming, upload the completed programming to the system, and have the engineer transfer it to the corresponding CNC machine with one click. The transmission process supports program verification to avoid equipment failures caused by program errors, and records program transmission logs to achieve full lifecycle traceability of NC programs.

At the level of statistical analysis and visualization, the system is equipped with professional report engines and visualization components: the report engine supports custom report design; The visualization component supports the construction of a digital twin workshop interface - based on the actual layout of the workshop, it displays real-time information such as equipment operation status, production task progress, and work in progress location; Simultaneously supporting on-site large screen display, deploying production progress dashboards, quality dashboards, equipment monitoring dashboards, etc., real-time refreshing key indicators (such as daily output, pass rate, equipment OEE), achieving transparency in production status.

What problems has MES system solved for customers?

More scientific decision-making: enable managers to shift from "experience based" to "data based" and make more informed decisions based on real-time and accurate report data.

Reviewing Budget Deviations and Planning for a New Journey—Ultra Light Holds the 2026 Annual Budget Preparation Meeting

Targeting Market Gaps and Strengthening Development Foundations | Establishment of Ultra Light Craft Technology Test Center

Ultra Light: The Pre-Acceptance of the Huade Cylinder Block Machining Project Concludes Successfully, Empowering Intelligent Manufacturing Upgrades in the Hydraulic Industry!

Ultra Light: Driving Traditional Manufacturing Towards a New Path of Digital and Intelligent Green Synergy Through Smart Manufacturing

Building a New Future for the Enterprise | The Official Establishment of Three Key Organizations: Ultra Light Party Branch, Trade Union, and Women's Group

Message

Message*Full Name

*Telephone

Message