In the wave of intelligent manufacturing, many enterprises have invested in transformation but achieved little effect. Why is the input and output not proportional? Behind it is often a cognitive bias that does not match the plan. This article summarizes the 5 major transformation misconceptions that 90% of enterprises have encountered, and provides practical avoidance suggestions to help you avoid pitfalls and make intelligent upgrades truly effective.

Misconception 1: Blindly pursuing automation, detached from production reality

Many companies simply understand "intelligence" as "unmanned" and follow the trend by investing in robots and automated production lines, without considering whether the product is suitable. For example, a certain mechanical processing enterprise invested a large amount of funds to introduce automated assembly lines, but due to the fact that most of the products were non calibrated parts, the equipment was frequently debugged and shut down, resulting in a final equipment utilization rate of less than 30% and a cost increase instead of a decrease.

✅

Key points for avoiding pitfalls: Avoid "automation for the sake of automation". It is recommended that enterprises start with workstations with high repeatability, high labor intensity, and strict precision requirements, and promote transformation in stages to ensure that each step effectively solves production pain points.

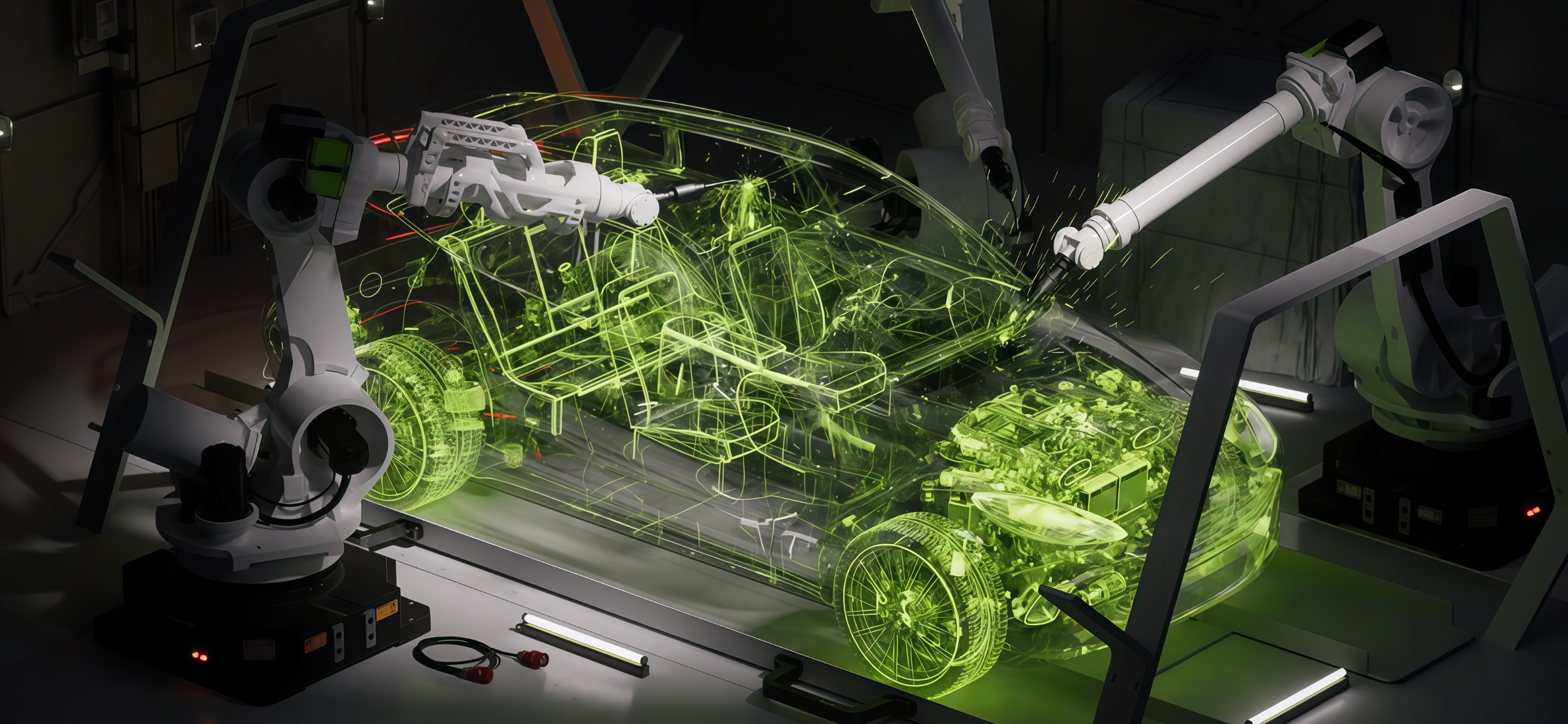

Misconception 2: Emphasizing hardware over collaboration, making it difficult to unleash the value of data

Some companies are enthusiastic about purchasing hardware equipment such as intelligent machine tools and robots, but neglect software systems and data connectivity. For example, a certain automotive parts factory invested heavily in introducing intelligent machine tools, but failed to integrate them with ERP, MES and other systems. Production data still relies on manual copying and filling, and advanced equipment ultimately becomes the "most expensive decoration".

✅ Key points for avoiding pitfalls: Before purchasing hardware, it is necessary to plan the data interface and system integration path to ensure that equipment data can be synchronized in real time to the production management system, forming a "device data system" closed loop.

Misconception 3: blindly copying the plans of large enterprises and ignoring one's own situation

Small and medium-sized enterprises have limited resources, and blindly copying the complex systems of large enterprises can easily lead to indigestion. For example, a certain food company invested in introducing a high-end intelligent platform designed for a large factory with tens of thousands of employees. As a result, the annual maintenance cost accounted for 15% of the annual revenue, and the system functions were largely idle. Employees were also unwilling to use it due to complex operations.

✅ Key points for avoiding pitfalls: Small and medium-sized enterprises are more suitable for the transformation path of "lightweight, modular, and step-by-step". You can start piloting from one section or workshop, choose cost-effective and easy-to-use solutions, and gradually expand the functionality.

Misconception 4: Data silos and low efficiency of cross departmental collaboration

Some companies only focus on dataization in a certain link when promoting intelligence, without breaking down departmental walls and industry chain information barriers. For example, in an electronics company, the production workshop has achieved data visualization, but the R&D department is still using traditional drawings and email communication, resulting in a 20% extension of the trial production cycle for new products.

✅

Key points for avoiding pitfalls: In the early stage of transformation, it is necessary to clarify the data integration goals, promote data exchange in research and development, production, supply chain and other links, and gradually extend upstream and downstream ecological collaboration for enterprises with conditions.

Misconception 5: Neglecting employee training, system disconnected from personnel

Enterprises invest a large amount of funds to upgrade equipment systems, but ignore the "upgrading of people". For example, after a household appliance company launched a new intelligent production line, it only provided one day of intensive training for its employees. However, due to unskilled operation and inability to handle faults, the product qualification rate did not increase but decreased from 98% to 92%.

✅

Key points for avoiding pitfalls: Intelligent transformation is not only a technological upgrade, but also an organizational capability upgrade. A graded training plan should be developed to cover the operational, management, and maintenance levels, and a trial operation and assessment mechanism should be established to help employees transition smoothly.

Ultra Light: Bring intelligent transformation back to reality and create practical results

In response to the common problems encountered by enterprises in their transformation, Ultra Light adheres to the principle of "demand-oriented, pragmatic implementation" and provides full chain accompanying services from diagnosis to training for enterprises.

Faced with "blind automation", Jiashun Aurora conducted in-depth on-site research before the project was launched to accurately identify high-value transformation links. For example, prioritizing the deployment of automated production lines for standard parts for a certain machinery enterprise, while retaining human-machine collaboration for non-standard processes, to achieve "return on investment and practical results in transformation".

Cracking the problem of "difficult data collaboration", Ultra Light's self-developed intelligent information management platform has high compatibility and can seamlessly integrate with common systems such as ERP/PLM, allowing device data to drive production decisions in real time and truly bring data to life.

For small and medium-sized enterprises, a "lightweight transformation package" is launched, using low-cost data collection tools and simple visual dashboards to help enterprises take the first step towards digitalization with low barriers to entry.

By bridging the "data silos", Jiashun Aurora can assist enterprises in building internal and external collaborative platforms, connecting research and development, production, and supply chain data, and even connecting upstream and downstream partners to achieve full chain transparency and controllability.

Supporting a 'layered training system', providing practical exercises for frontline employees, and conducting data analysis and application training for management personnel to ensure efficient integration of 'people, systems, and equipment'.

Ultra Light is willing to be your practical partner on the road of transformation. Through the full process service of "diagnosis solution implementation training", we will help you avoid common pitfalls and embark on a path of intelligent manufacturing upgrade that is tailored to yourself and steadily implemented.

Message

Message