The soaring labor costs, production efficiency bottlenecks, difficult to control quality fluctuations, and lagging market responses... Traditional factories are deeply trapped in survival difficulties, with every pain point compressing their development space.

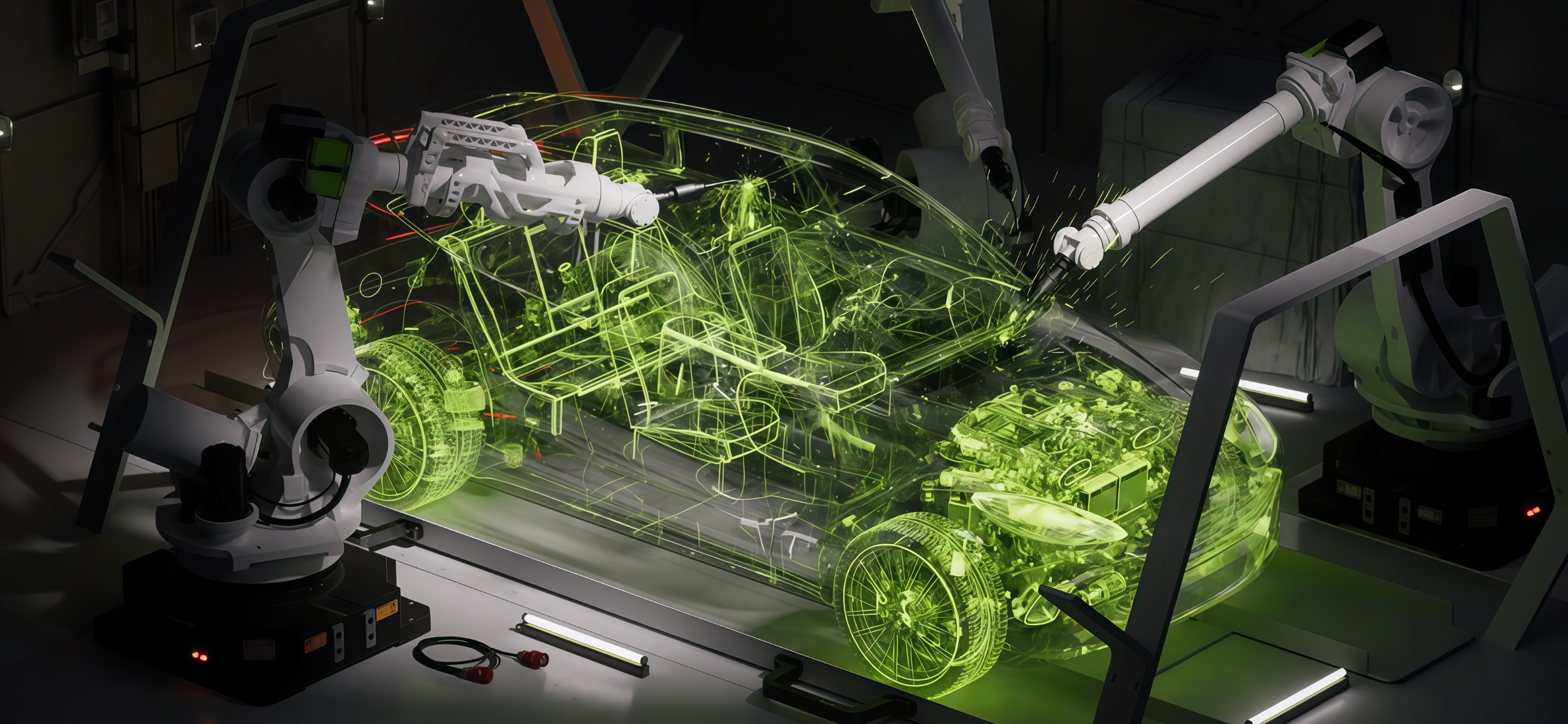

The key to breaking the deadlock lies in intelligent transformation. Reduce labor costs through automation, increase efficiency through digitalization, stabilize quality through intelligent detection, adapt to personalized needs through flexible production, and achieve scientific decision-making through digital twins. Ultimately transforming into a data-driven modern intelligent manufacturing enterprise.

The pain points of traditional factories are precisely what automation can solve

1. High costs: Labor costs are increasing year by year, and equipment energy consumption is huge.

Intelligent transformation: It can reduce long-term labor costs by replacing repetitive and high-intensity manual positions with automated production lines and robots. Monitor device energy consumption through IoT technology, optimize production processes, and reduce energy waste.

2. Difficulties in breaking through efficiency bottlenecks: Production relies on the experience of experienced masters, the production process is opaque, and the phenomenon of information silos is severe.

Intelligent transformation: MES system, ERP system and other systems can be used to connect data from various departments and achieve visualization of the entire production process. Through data analysis and AI algorithms, optimize production scheduling, predict equipment failures, and maximize equipment utilization.

3. Poor quality stability: Product quality relies on manual testing, with high rates of missed or misjudgment, making it difficult to trace the root cause of problems.

Intelligent transformation: Introducing machine vision for automatic quality inspection, with precision and efficiency far exceeding manual labor. By assigning codes (such as QR codes, RFID) to products, we can achieve full lifecycle quality traceability from raw materials to finished products.

4. Slow market response: The large-scale production model is difficult to adapt to the trend of personalized customization with small and multiple batches.

Intelligent transformation: Build flexible production lines, use digital platforms to receive orders, quickly adjust production parameters, achieve "on-demand production", and seize opportunities in segmented markets..

5. Decision making relies on "brainstorming": Management lacks real-time and accurate data support, and decisions are often based on experience and intuition, resulting in high risks.

Intelligent transformation: By building "digital twins" in factories, simulating and optimizing production in a virtual world, providing scientific data dashboards and predictive analysis for management decisions.

How to move towards intelligence? A pragmatic roadmap

Step 1: Diagnosis and Planning

Clear goals: Set clear and quantifiable transformation objectives. For example, "within one year, increase the overall efficiency of equipment by 10%" and "reduce the product defect rate to one in ten thousand".

Step 2: Establish a solid digital foundation

Device networking: Install sensors on key devices to collect data on operating status, output, energy consumption, and more. This is the source of all intelligent data.

Deploy core system: Use MES system to break the "black box" of the production site and achieve real-time transparency of production progress and quality data. Then integrate the MES system with existing ERP, WMS systems, etc., to break down information silos.

Step 3: Local Automation and Intelligence

Machine substitution: Introducing industrial robots or automation equipment in highly repetitive, labor-intensive, or hazardous workstations such as welding, spraying, loading and unloading, and handling.

Intelligent Quality Inspection: Introducing machine vision inspection equipment in critical quality processes to replace manual visual inspection.

Predictive maintenance: Based on equipment operation data, predict possible failures, change from "repair before failure" to "repair before failure", and reduce unplanned downtime.

Step 4: System integration and data-driven approach

Building a data center: Collecting data from various systems and devices together for unified management and analysis.

Application of AI algorithms: Utilizing data to optimize production process parameters, perform intelligent scheduling, predict market demand, and achieve supply chain collaboration.

Building a digital twin: constructing a factory model in a virtual space for simulation, monitoring, and optimization, achieving true intelligent decision-making.

As a practitioner in the field of intelligent manufacturing, Ultra Light focuses on the core pain points of enterprises with rich experience in intelligent factory transformation, and provides one-stop solutions for factory transformation. Jiashun Aurora not only provides a guarantee for the factory to survive, but also lays the foundation for its future participation in competition at a higher level.

Message

Message