ABOUT US

About us

Service

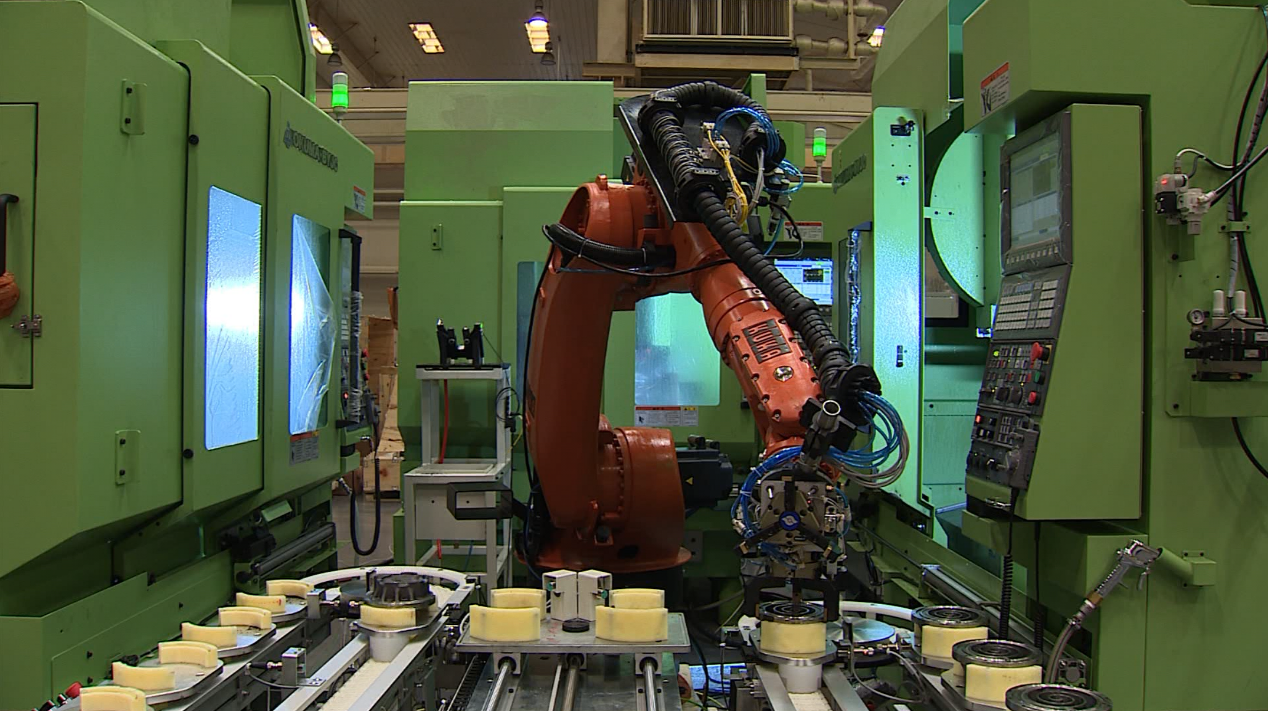

ServiceFuel injection shaft

Fuel injector, fuel injection shaft, vertical machining center, lathe assembly line, automated production line, articulated robot, automatic loading and unloading, flexible unit, flexible machiningRead More >>

Stryker: Single machine collaborative workstation

A set of automatic loading and unloading systems corresponds to the monitoring of one machine tool, with the option to choose between automatic or manual (offline) control modes, capable of completing unmanned and automated production for a certain period of time.Read More >>

Tianma Control: Automated Pump Head Assembly Production Line

The system can flexibly handle the assembly requirements of all 13 products in Tianma Zhikong's large-component series, ensuring each product is assembled efficiently and accurately on the same production line. Through meticulous demand analysis and customized solution design, Jiashun Aurora ensures every project phase aligns with practical applications, ultimately achieving the desired outcomes for both parties.Read More >>

Compression motor, fixed disc

Vertical machining center, articulated robot, compressor, moving disc, fixed disc, automatic loading and unloadingRead More >>

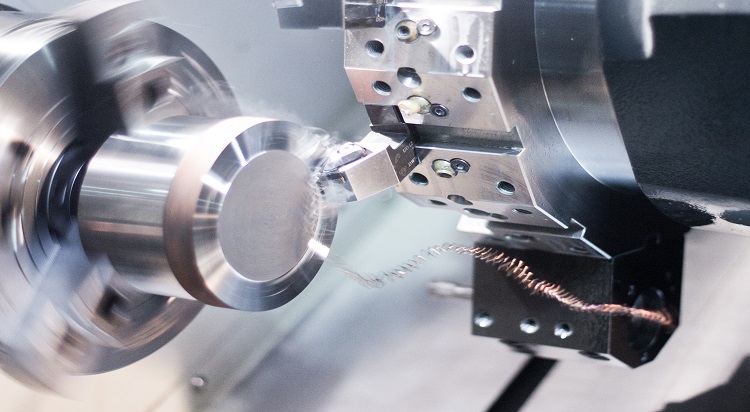

Single machine lathe FMS

Lathe, lathe FMS FMS、 Automated production line, manufacturing unit, flexible processing, flexible productionRead More >>

FMS

Flexible Automation System Intelligent Manufacturing Unit FMS of a Military Industry Enterprise Aluminum alloy miscellaneous parts processingRead More >>

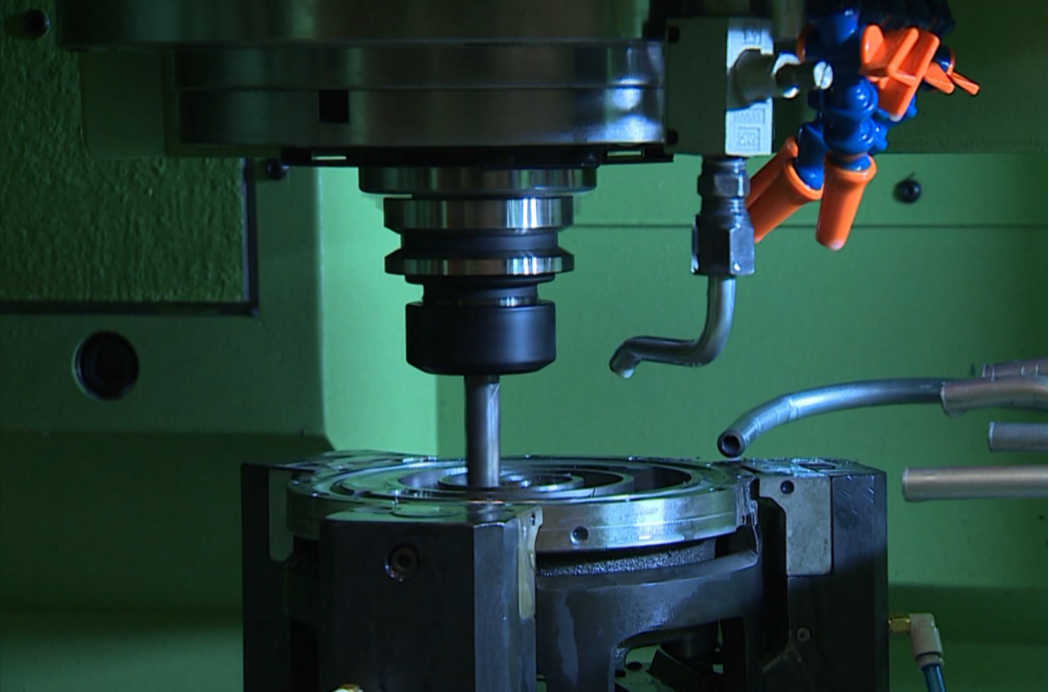

Automated machining unit for hydraulic motor stator

Flexible automation machining unit for stator of hydraulic motor used in construction machineryRead More >>

Motor back cover

Motor back cover: This project is a turnkey project. We provide customized solution research and development for customers, successfully helping them obtain orders from the United States. At the same time, we complete self production of previously difficult to control outsourced parts, reducing single unit costs by more than RMB 1.Read More >>

Construction machinery shaft

Sales axis intelligent manufacturing unit, automated production line, engineering machinery, sales axisRead More >>

clutch housing

Automotive industry, automated production lines, lathes, turning centers, automatic loading and unloading, flexible unitsRead More >>

Automotive Parts FMS

Automotive parts, FMS flexible manufacturing unit, stacking, pallet three-dimensional warehouseRead More >>

PREV

NEXT

PREV

NEXT

NEWS

News

24

MORE+2025-12

Reviewing Budget Deviations and Planning for a New Journey—Ultra Light Holds the 2026 Annual Budget Preparation Meeting

To thoroughly implement the medium- and long-term corporate development strategy, scientifically coordinate the operational and developmental plan for 2026, and fully leverage the core supporting role of budget management in corporate operations, Ultra Light recently officially convened the 2026 Budget Planning Conference.

18

MORE+2025-12

The critical moment of "artificial intelligence + manufacturing": not cost reduction, but reconstruction

Reconstructing a true future-oriented manufacturing system

10

MORE+2025-12

Targeting Market Gaps and Strengthening Development Foundations | Establishment of Ultra Light Craft Technology Test Center

Ultra Light Process Technology Experimental Center was established in Beijing (Tongzhou). Function 1: Serve as the process R&D center for new machining technologies in key industries and specialized fields for Ultra Light, providing process services to clients. Function 2: Address the shortage of small-batch, high-precision, and customized machining resources in the market by delivering prototype manufacturing for clients. Function 3: Support the parts machining of prototype models for Ultra Light's self-developed products.

Message

Message*Full Name

*Telephone

Message